LIFEBOAT INSPECTION

Service maintenance of lifeboats in PHB- PHUONGHONG MARINE SERVICES meet IMO regulations 761 (18) and is authorized by 07 leading manufacturers. PHB- PHUONGHONG MARINE SERVICES full processes and equipment to maintain the same strong technical team of professional, experienced.

Service maintenance of lifeboats in PHB- PHUONGHONG MARINE SERVICES meet IMO Regulations 761 (18) and is Authorized by 07 leading manufacturers. PHB- PHUONGHONG MARINE SERVICES processes and equipment to Maintain full strong technical team of professional, experienced

Check first

– Annual check

– Check five years

– Try loading lifeboats and lifting equipment in load 1.1 times working load (each 5 years).

FIRE FIGHTING & MANAGE ON SHIP

The most important thing is not to onboard fires. If the unfortunate happens, they must know the fire extinguishing efficiency. For this, need good management and maintenance of fire systems aboard.

Based on the diagram of firefighting, “Fire control plan”, the person in charge of fire fighting equipment have established track records maintenance firefighting equipment periodically. Depending on the size and route of each ship equipped with appropriate fire-fighting system. However, the service equipment on board the firefighting often is:

1. EQUIPMENT FIRE ONBOARD

– The fire nozzles

– Internal shore connection

- Portable fire extinguishers, including:

– The fire extinguisher foam (foam)

– The fire extinguishers, gas (CO2)

– The extinguisher chemicals (chemical)

– The fire extinguisher powder (powder)

– The fire extinguishers Other reserve ( spare-charges)

- Fixed fire extinguishing system engine room, cargo hold are:

– CO2 fire extinguishing system,

– gas extinguishing systems (inert gas, helon)

– Foam fire extinguishing systems (foam)

– System extinguishing spray (spinkler) - Oil shutoff systems, wind, ventilation and emergency exits, including:

– Ventilation system

– Venting pipes

– Dampers

– Emergency shut down

– Fire doors & controls

– Escape routes

Emergency escape breathing devices

FIRE STATION or FIREMAN OUTFITS, including:

– Ffire jacket, pants, gloves, cap, boots

– Breathing apparatus

– Fire axe

– Fireman lifeline

– Safety light

INSPECTION AND MAINTENANCE EQUIPMENT FIRE ONBOARD

General Regulations on inspection

of fire fighting equipment should be checked and maintain reliability. Maintenance work must be carried out periodically (weekly, monthly, quarterly and annual). The purpose of the maintenance is to ensure the firefighting equipment is always ready to work state. Calendar maintain and check the following:

(1) Check weekly

– Try operational information systems and internal communication (public address system)

– Try activities Alarm System General (general alarm)

– Check breathing (breathing apparatus cylinders) and compressed air leaks

– Check the status of the outside, the installation location prescribed equipment (2) Check the monthly

– Check the number, location of installation, store and general condition of the equipment of firefighting under the layout and equipment of firefighting vessel

– Check the position of the valve of fire extinguishing system fixed, have put in place “closed” or “open” as prescribed.

– Check the specified index of the clock pressure wind bottle launch fire extinguishing systems, the spacer … is at regulation.

– check valve position indicator and clock regulated pressure wind bottle valve control system quickly.

– Try to operate the pump fire pumps including fire incident, the pressure dragon fire. Check the leakage of piping, valves, taps and dragon fire

– Try operating the fire alarm general, the fire alarm sector

– Testing equipment automatically shut the door against fire

(3) Check the row precious

– Content such as checking monthly

– Try active sensors Fire alarm

– Try operate the hand valve closed ventilation system, ventilation, blocked fire … (dampers)

– Try operating the valves of firefighting, the valve block (stop valves)

– Check control wire fire system CO2

– Check operating system fire warning automatic fire extinguishing system fixed

– Check active fire fighting systems misting (spinkler system )

4) Check the annual

Work annual inspection conducted by the crew and the company commissioned onshore. The company was commissioned (RO), check the following items and make report to the registry as follows:

+ Replace new foam to foam, add more pressure gas bottles (if weight reduction of over 10%), or rather the average powder flour if dough is moist.

+ Check and additional pressure on the spacer (SCBA), the breathing problem (EEDB), bottles of compressed air

+ function test fire alarm system

+ test system operation public information

+ Try alarm General fire action

+ try alarm fire area

+ try operating system quick closing valve

+ try automatic alarm fire fighting system fixed fire

+ Try operating the fire pumps, including fire pumps incident

+ Testing pressure of dragon fire, nozzles

+ Testing activity Fire extinguishing systems spray warehouse paint

+ Quality control equipment loaded air (if available)

+ Check the instructions, operating instructions and equipment, labels-labels of prescribed fire IMO

- Periodically check the special

WW special inspection will be conducted by the company mandated (RO).

After checking satisfies criteria, must issue certificates of

safe use of the equipment is checked as follows:(1) Periodically 2 years

– Check the volume of CO2 of the average in the fire-fighting system fixed

– try enclosed pipe system extinguishing gas(2) Periodically 3 years

– check the quality of the foam system fixed fire

– then be checked annually(3) Periodically 5 years

– try pressure compressed gas cylinders (SCBA)

– on testing and pressure testing must be clearly stated on each bottle(4) Periodically 10 years

– Check inside the control valve fixed fire-fighting system

– Try checking pressure fire extinguishers, portable

– On and data on the pressure test is indicated on each bottle(5) Periodically 20 years

– Try pressure cylinders CO2 fire extinguishing system fixed after manufactured 20 years.

Then, every 10 years to check back once.

– Date and pressure tests specified on each bottle.

provisions of IMO 761 (18) and is authorized by 14 leading manufacturers with the complete process and equipment for maintenance. Strong team of professional technicians, experienced has been trained and certified by each manufacturer.

LIFERAFT

Liferaft lifesaving equipment is very important and indispensable for all rescue boats cruise along with Ng of emergency, life rafts launched easily and quickly lifeboats. Besides, life rafts designed inflatable system automatically, saving the maximum time to evacuate.

WHY MAINTENANCE LIFERAFT IMPORTANT?

Liferaft survival equipment on board is extremely important, to ensure the safety of seafarers in case of an emergency.

Liferafts maintenance to comply with the regulations on ship safety equip, secure circulation.

Periodic maintenance checks to control the operational status of the device, saving costs and ensuring human life and property on board.

At PHUONGHONG MARINE SERVICES technician staff is trained and certified to comply with service processes of each specific NSX. We provide maintenance services life rafts under the provisions of IMO 761 (18) and is authorized by 14 manufacturers:

- SG SAFETY COOPERATION(KOREA) (All types: SG-SV and SG-D)

- SHANGHAI STAR RUBBER PRODUCTS CO., LTD– (All types: RAFT and SMLR)

- SHANGHAI YOULONG RUBBER PRODUCTS, LTD – (All types: KHB; KHA; KHZ; KHD; KHZD; KHR; KHK; KHY; KHYJ and KHY(SR))

- SHANGHAI HUAXIANG DACHENG RUBBER & PLASTIC CO., LTD– (All Types: HYF and QJF)

- NINGBO HAIFENG LIFE-SAVING APPLIANCE MANUFACTURING CO., LTD – (All types: CRV: CRVF-A; CRVF-D; CRVF-U; CRVF-Z)

- JIANGSU HAINING MARINE EQUIPMENT CO., LTD(All Types of HNF)

- SHANGHAI HAIAN LIFE-SAVING EQUIPMENT CO., LTD – (All types: HAF-A; HAF-D and HAF-K)

- NINGBO NEPTUNE LIFE-SAVING EQUIPMENT CO., LTD– (All Types: ATOB; ADL; ADLSR; ASR; AOR; YT; YSR; YJT)

- SHANGHAI CUNHONG MARINE LIFESAVING APPLIANCE– (All Types of CUNHONG & SAFINDO including “CHF” & “SLR” series)

- SHANGHAI CUNHONG MARINE LIFESAVING APPLIANCE– (All Types of TOKUGAWA including “DLR” series)

- SEAMAN SAFETY – MODEL: SEAWOLF– All Types

- SEAMAN SAFETY – MODEL: SEAMAN– All Types)

- NINGBO ZHENHUA LIFE-SAVING EQUIPMENT CO.,LTD– (All Types)

- NINGBO ASIA F.R.P BOAT MANURACTURING CO., LTD – (All Types)

CONTACT PHB TO PERFORM INSPECTION AND MAINTENANCE life rafts | Process inspection and maintenance professional, transparent and time-saving.

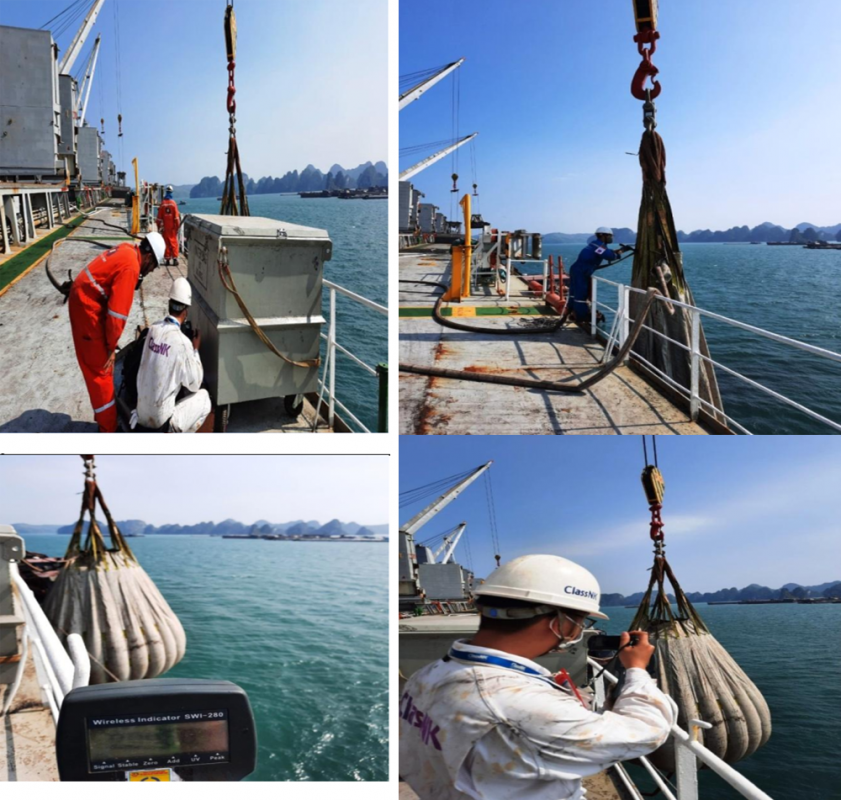

LOAD TEST FOR CRANES/ DAVITS

We carry out work related to load testing as follows: – Load test for cranes / pipes – Load test for davits of lifeboat and life raft

Service load testing cranes in PHB- PHUONGHONG MARINE SERVICES enhanced with water bag – modern solutions are being appreciated for their benefits as a safe, fast, high economic efficiency … PHB- PHUONGHONG MARINE SERVICES always upgrades services using modern methods in order to shorten the time and optimize efficiency. All these improvements have contributed to upgrading the value of our services.

We carry out work related to the load test is as follows:

– Try loading cranes cargo

– Try loading cranes food

– Try loading rack pipeline

– Try loading crane lifting life rafts and lifeboats

Equipment try include:

– Dynamometer type 5 tons, 25 tons, 50 tons, 100 tons of the remote control.

– Loading bags diverse countries. Total load test up to 100 tons.

+ TRY LOADING CRANES CARGO

+ TRY LOADING CRANES FOOD

+ LOAD TEST ENGINE ROOM CRANE

PHUONGHONG MARINE SERVICES TEST WATER BAGS – INNOVATIVE SOLUTIONS AND EFFICIENCY

Currently, the water bag load test is favored by the test method is simple and safe to download instead crane load test with traditional solids.

LOAD TEST WATER BAGS

Load test for Cranes / Davits Quy provisions of SOLAS (Refer to SOLAS Part 1, Chapter III, Regulation 20) and the provisions on lifting equipment (LOLAS) requires all ships to inspect load testing for equipment release of lifeboat release and equipment amounted to 110% load rated power for a period not exceeding 5 years.

Currently, the water bag load test is favored by the test method is simple and safe to download instead crane load test with traditional solids.

ADVANTAGES WATER BAG WITH CRANE LOAD TEST:

– Safety: load test water bags are tested and certified for safety coefficient physically reached 6: 1. In addition, the water bag load test helps early detection of potential problems. Thereby giving the remedy, replacement or maintenance.

– Efficiency for load testing be most types of lifting equipment. Moreover, the lift is designed separate from the bag body of water, ensuring no impact when something went wrong. Currently on the market there are many types of load testing bag with lifting capacity from 1 ton to 100 tons.

– Reasonable price: Due to the special material to withstand the harsh conditions so the load test is very reliable bags, bring high economic efficiency.

– Convenience: Water makes up nearly 98% at full load weight, so when empty pockets quite light and easy storage and transportation. Bag designed easy filling and discharging, detachable and equipped with automatic pressure relief valve.

PHUONGHONG MARINE SERVICES provides crane service load testing and inspection services, maintenance, certification for life-saving equipment, fire on board. We are certified by ISO 9001, Japanese registry, registry Korean, French registry, registry Vietnam … PHUONGHONG MARINE SERVICES full processes and equipment to maintenance and professional sound technician staff experienced has been trained and certified by each manufacturer.

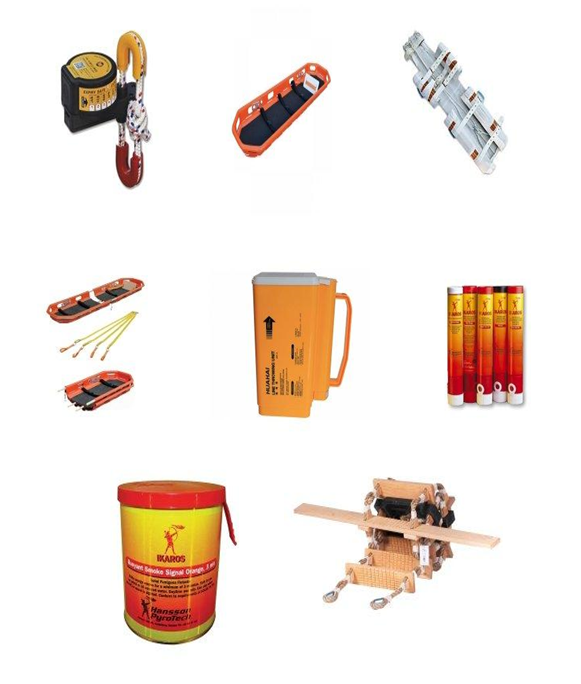

PHB-SUPPLY PRODUCT MARINE SAFETY EQUIPMENTS

MARINE SAFETY EQUIPMENTS

LIFE-SAVING EQUIPMENTS

FIRE FIGHTING EQUIPMENTS

MARINE ELECTRONICS EQUIPMENTS

OTHER EQUIPMENTS

Contact us:

Phuonghong Ship repair and Marine Services Co. Ltd

- Head office

Address: 7/1 So Dau street – Hong Bang District – Hai Phong City

Mobile / WhatsApp/ WeChat: +84 793331062

Email: info@phuonghongmarine.com

- Ship repair services in Ho Chi Minh City

Email: phuonghongtechnical@gmail.com

Mobile / WhatsApp/ WeChat +84 793331062